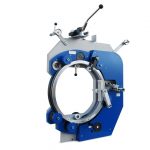

The RWS-Evolution is the high end floor toroidal winding machine base from RUFF. The new controller with innovative programming is user friendly and through the high resolution touch screen display it is simple to understand. Programs are saved in CSV-Format.

Therefore, programs can be made external by Excel. The Windows system allows own data management saved onto USB-Stick, or onto the CF-Card in a seperate file on the

machine. A central program management at an external PC (Server) is possible via Ethernet connection. Easy file structure can be created and every program can be reported with a text description. The machine can also be remote controlled by Ftp- connection. Teleservice by our technicians via internet connection (Ftp- connection) for trouble shooting

in the logic program. Update of PLC and visual display software via USB Stick, datas can be sent via E-mail.