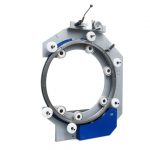

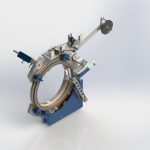

The machine bases are available in two versions:

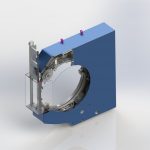

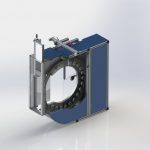

RW 55-Evolution with a fixed winding head and RW 55-Evo-Shuttle with a moveable winding head. The machine base in Shuttle-Version has a slide system for the

winding heads. It enables to move the winding heads out of the winding area for a comfortable load and unload the machine with toroidal cores (e.g. with a crane). This system brings especially for very large or very heavy cores crucial advantages. Programs are saved in CSV-Format. Therefore programs can be made externely by Excel. The Windows system allows own data management saved onto USB-Stick, or onto the CF-Card in a seperate file on the machine. A central program management on an external PC (Server) is possible via Ethernet connection. Easy file structure can be created and every program can be reported with a text description. The machine can also be remote controlled

by Ftp-connection. Teleservice by our technicians via internet connection (Ftp-connection) for trouble shooting in the logic program. Update of PLC and visual

display software via USB-Stick, datas can be sent via Email.