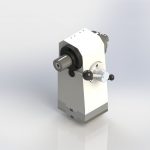

The LW 27 is our precision machine, equipped with an integrated electrical cabinet and a tailstock with its own table frame. It was specially designed for the production of demanding precision winding applications with small winding bobbins and it has an impressive speed of up to 12,000 RPM.

The machine bed is welded and subsequently processed on a multi-axis milling machine, ensuring the highest precision from the spindle to the tailstock. Typical applications include windings with high numbers of turns, where both precision and speed are essential.

The intuitive control system, available in all languages, allows for easy operation via a generous 12-inch touchscreen with Android or a 15-inch touchscreen with Windows operating system. With the USB interface, programs can be easily input and output, while network connectivity and remote maintenance options provide you with full control over your production.

An additional highlight is the workplate mounted under the machine, which can be swung in or out as needed, further enhancing workflow efficiency.

Of course, we also offer a wide range of accessories for the LW 27, including wire brakes, wire guides, and more, ensuring that you get the most out of your machine.