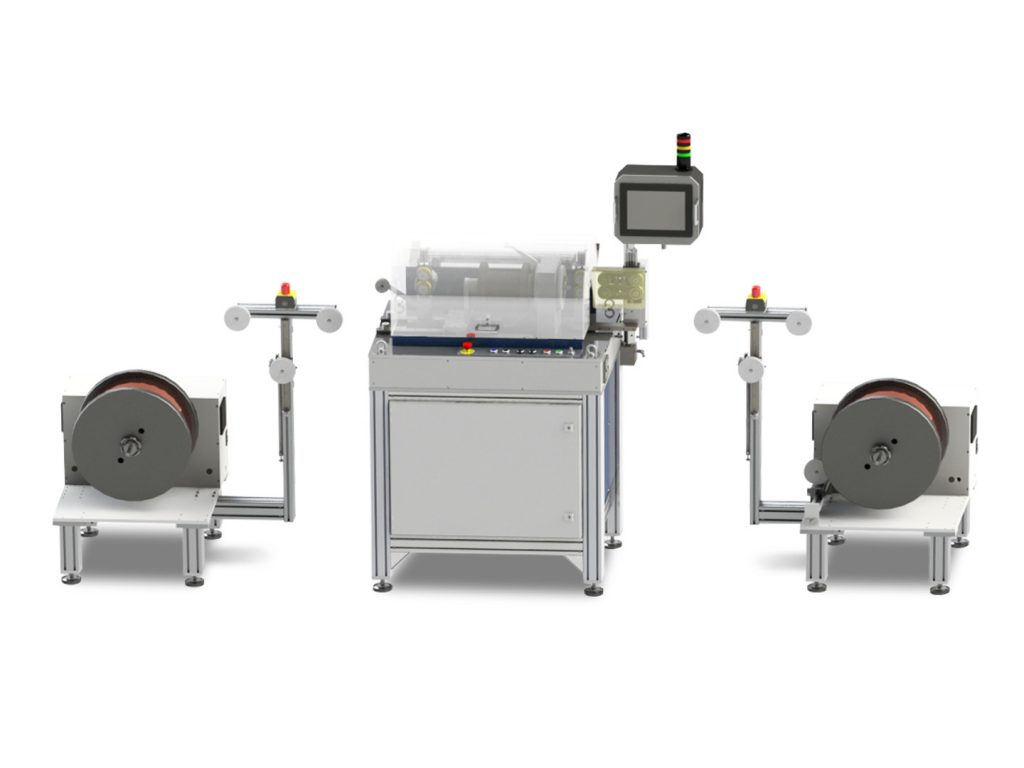

Heavy duty spiral winding machine for large wires and big wire spools

This automatic high speed spiral winding machine is designed for continuous winding onto endless carrier material with permanent wire pitch or several different lengthswith each independent pitch.