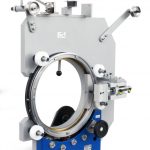

RUFF has designed a low cost standardised taping station in order to replace the oneway special and expensive double head machine. It is a flexible taping system that can be placed next to existing toroidal winding machines and therefore enables simultaneous winding and taping of transformers in the most economical method. The head is mounted on a ground plate which sits on sliding rails and enables to slide the head easily into the core. It incorporates the RUFF modular system and can be equipped with interchangeable

heads. One or more working stations can be combined with a winding machine.

Applications

Nothing Found