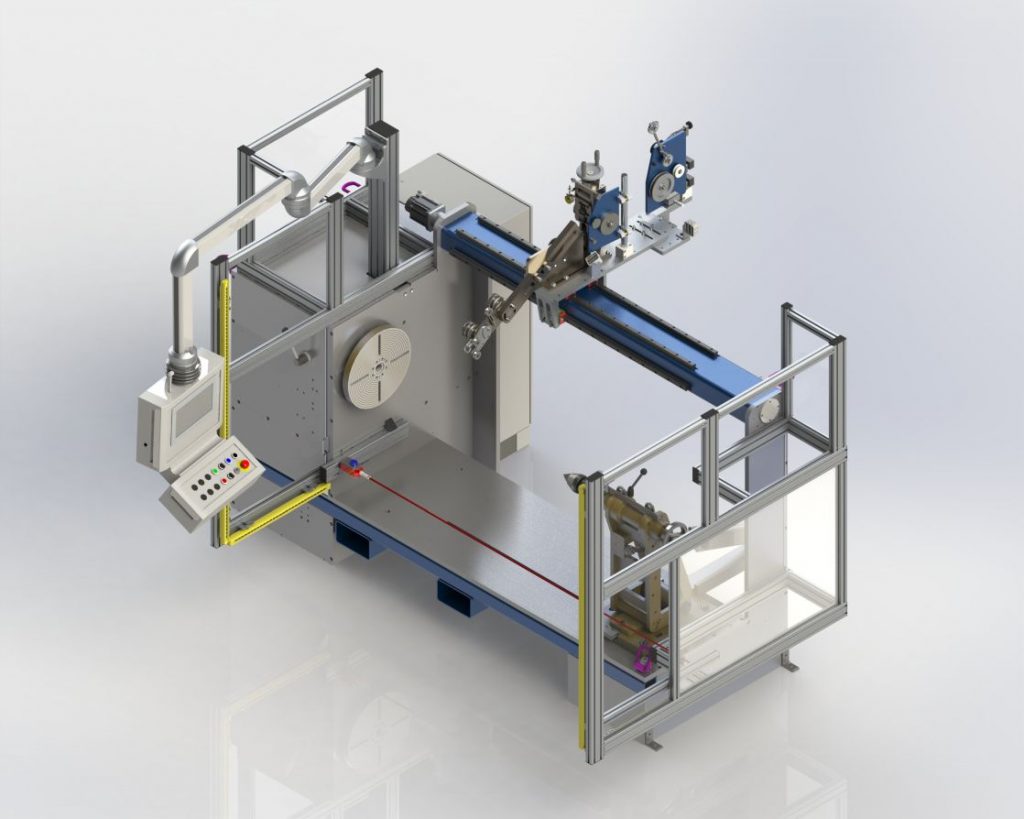

The LW 152 sets new standards in power and versatility. This robust floor machine with steel welding construction and tailstock is a true workhorse, effortlessly tackling even the most demanding winding tasks. From primary to secondary winding, it offers the perfect solution for every application.

Thanks to its 3-step gearbox, it is ready for any challenge and can be expanded with an additional reduction gearbox if needed to handle even the most complex tasks. Large winding diameters and the finest wire windings are no problem for it, and its extended laying width of 1400 mm allows for even more flexibility.

Operating the LW 152 has never been easier. With a generous touchscreen, available in either Android or Windows operating system, and an intuitive user interface, you can easily input and manage your programs. The USB interface allows for easy input and output of programs, while network connectivity and remote maintenance options give you full control over your production at all times.

And of course, we also offer a comprehensive selection of accessories for the LW 152, from wire brakes to wire guides, to ensure that you get the most out of your machine.